This will likely really feel like specialist knowledge, however for severe engine developers and residential mechanics with a venture themselves, checking the pushrod size is also a ache within the neck, however it is price doing. Even though you are operating with a hydraulic lifter setup, you’ll briefly put the factory-length pushrods out of spec with only a few upgrades. Milling your heads, having a valve task finished, decking the block, all of the ones little adjustments can stack as much as paintings towards you, as each and every decreases the vital pushrod size.

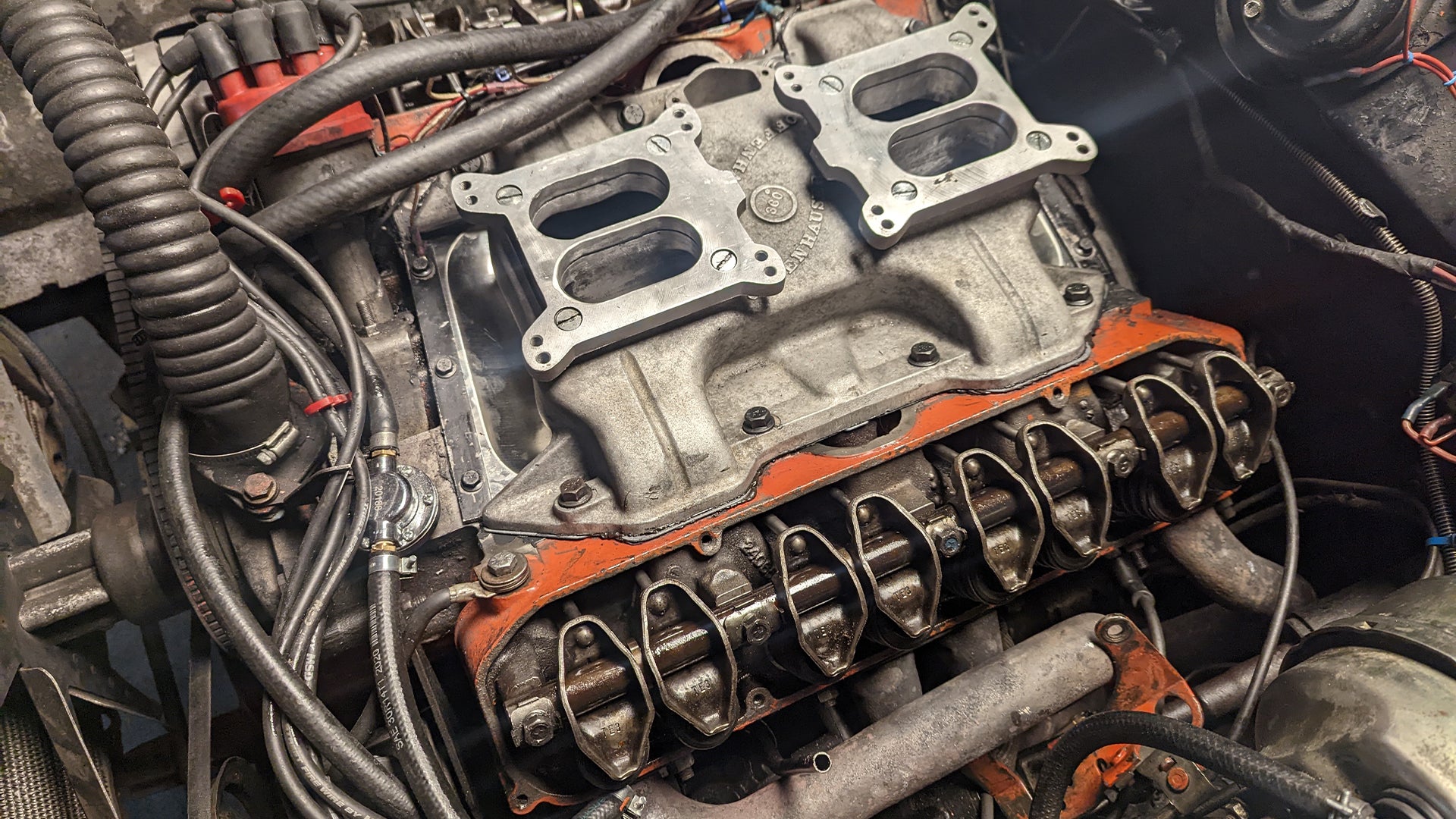

Having too lengthy of a pushrod in any engine could cause a wide variety of problems. Valves striking open, lifters pumping up, harm to the valvetrain, and different performance-killing signs are at the menu. Those problems are dangerous for any engine, however it sort of feels like lots of the knowledge available in the market relating to discovering pushrod size is proven on a small block Chevy or LS engine. Whilst the guidelines given in that structure is normally the similar, small adjustments within the process are made when shifting to an engine with even relatively other genetics. That is why I need to stroll you via how I in finding pushrod size in a large block Mopar engine with constant rockers.

The Pressure and its companions would possibly earn a fee if you buy a product via one among our hyperlinks. Learn extra.

The whole thing You’ll Want To Measure Pushrods

Contents

- 1 The whole thing You’ll Want To Measure Pushrods

- 2 Right here’s How To Measure Pushrods

- 3 1. Get entry to the Lifter Valley

- 4 2. Set up Rocker Shaft

- 5 3. Take away the Spark Plugs (Non-compulsory)

- 6 4. Get On The Base Circle

- 7 5. Slide Dimension Software in Position

- 8 6. Unwind to 0 Lash, Counting Rotations Alongside the Means

- 9 7. Upload the Worth of Rotations to Software Period

- 10 8. Resolve Preload

- 11 9. Report and Repeat

- 12 Video

- 13 Extra From The Pressure

There are numerous techniques to measure pushrod size. Fortunately, probably the most fundamental strategies are viable for this sort of engine. For the document, the 440 we are operating on is provided with a hydraulic flat tappet cam and stuck shaft-mounted rocker fingers. On this case, all you in point of fact want is a pushrod measuring instrument and a few fundamental hand gear to show the engine over manually and to take away the consumption and valve covers, if they are in position.

Organizing your gear and tool so the entirety is definitely reachable will save treasured mins looking forward to your handy-dandy kid or four-legged helper to carry you the sandpaper or blowtorch. (You will not want a blowtorch for this task. Please don’t have your child hand you a blowtorch—Ed.)

Right here’s How To Measure Pushrods

1. Get entry to the Lifter Valley

First issues first, get the consumption out of the way in which. In case you are construction an engine from the ground up, that isn’t a lot of an issue. Then again, the ones folks taking corrective measures through addressing pushrod size after the truth simply need to chunk the bullet. Getting it out of the way in which provides you with various room to paintings. Whilst you’re at it, take away the valve covers and get the present pushrods out of the way in which.

2. Set up Rocker Shaft

Subsequent is to set the rocker assemblies up. Bolt them at the heads as they might generally sit down and torque them to spec. In case you are operating with a Chrysler B or RB engine, 25 lb-ft is your magic quantity.

3. Take away the Spark Plugs (Non-compulsory)

Leaving the spark plugs in position is not going to modify your measurements. It is going to simply make rolling the engine over more difficult to do. You’ll and can save your self numerous cursing through simply taking them out previously.

4. Get On The Base Circle

The right kind pushrod size is located with the valve totally closed. That implies you wish to have to roll the cam lobe for the valve you are checking onto its base circle. Since we’re operating with a 440 with out the consumption, that is one thing we will bodily see in this engine. Regardless that, you’ll at all times watch the location of the lifters to make certain. If the other valve lifter is emerging to its height, you realize the only you are operating on is at the base circle.

5. Slide Dimension Software in Position

That is the place giving your self all that room to paintings goes to begin to repay. Even though the pushrod measuring instrument is shorter than inventory pushrods earlier than changes, some finesse is so as.

I discovered it highest to begin with the bottom of the instrument within the lifter, then pop it up beneath the rocker arm. Ahead of you do it, ensure that the tip of the instrument you’re taking your measurements from is down within the lifter valley, as that makes it a lot more straightforward to peer and paintings with.

6. Unwind to 0 Lash, Counting Rotations Alongside the Means

Those pushrod dimension gear paintings rather merely. They’ve a threaded finish with a scribe that traces up with the principle frame. Rotating the threaded finish counterclockwise successfully extends the size of this pushrod. Usually, each and every complete rotation, or each and every time you spot the scribed marks line up, it is prolonged .050 inches. However you do not want to do the maths presently. You simply want to begin with the scribed marks dealing with you able you’ll simply learn them.

As soon as you are there, get started counting rotations counterclockwise till you haven’t any lash or 0 slop within the meeting. You might be no longer looking to bind the instrument up towards the rocker and lifter, simply going till there is not any play.

7. Upload the Worth of Rotations to Software Period

As soon as you have counted the collection of rotations it takes for the pushrod measuring instrument to soak up the slack for your meeting, it is time to perform a little math to seek out the suitable pushrod size. You might be merely multiplying the collection of rotations through the size won with each and every rotation and including that to the minimal size of the instrument you are the usage of.

In my case, each and every rotation features .050 inches, which can be added to my instrument’s minimal size of 8.8 inches. If It takes me 9 rotations to succeed in 0 lash, I multiply 9 through .050, giving me a worth of 0.45. Subsequent, I upload 0.45 to eight.8, telling me that the pushrod measuring instrument prolonged to 9.25 inches.

When you’ve got a caliper with a big sufficient opening, you’ll use that to measure this size as an alternative. Merely repeat the collection of rotations it took to succeed in 0 lash, and measure all of the size together with your calipers.

8. Resolve Preload

We are not finished with the maths homework simply but. We nonetheless want to decide how a lot preload the engine wishes. Preload principally refers back to the minute quantity the pushrod will have to be compressing the hydraulic lifter whilst at the base circle.

Fortunately, a spread is normally given through the producer of o.e.m or OE lifters, with one thing like .020-.060 inches of preload being not unusual. With the examples given, we will accept one thing down the center and upload .040 inches to the 9.25 inches discovered previous, giving us the specified pushrod size of 9.29 inches.

9. Report and Repeat

Take the fascinating total pushrod size you discovered, log it into your notepad beneath the suitable valve and cylinder, and get in a position for extra. It is very important take a look at the other valve for that cylinder you began on, as consumption and exhaust pushrod lengths are matter to variation, particularly for those who’ve had valve paintings finished.

Some people will accept measurements taken on only one cylinder. Others would possibly paintings in an ‘X’ trend, taking measurements from simply the 4 corners of the block. Then again, I feel it is price checking all of them as you have already come this a long way, so you may as smartly accumulate all of the knowledge that you’ll.

Video

Yeah, we coated numerous little steps, and all that textual content can also be complicated in case you are a visible learner. That is why I popped within the video under. It walks via all of the identical steps, most effective on a V6 engine, versus the Chrysler RB engine we are operating on. The method is the same, although, and is going to turn that it is viable for greater than only one software.

Extra From The Pressure

supply Via https://www.thedrive.com/guides-and-gear/measure-pushrods-fixed-rocker-engine